$1.9B+

98%

In component orders processed

Independent order placement

Why component manufacturers choose Allmoxy

Faster Flows

Eliminate order entry bottlenecks

Full Customization

Fully customizable products and pricing formulas

Powerful Automation

Automate order updates, collections, and communications

Accelerate Production

Accelerate time to production with customizable machine exports

Control Collections

Multiple payment options, account limits, interest charges, shipping calculations, and more

Operational Insights

Forecast, benchmark, and reflect with robust reporting

See how Allmoxy serves

Transform Your Customer Ordering Experience

Enable customers to configure and order with confidence

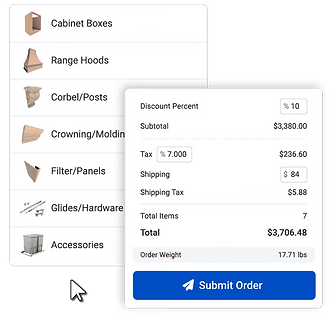

Online Ordering with Custom Configuration

Formula-based pricing for complex dimension calculation

Real-time pricing based on materials, dimensions, and labor

Automated validation rules preventing non-manufacturable orders

Self-service portal to eliminate phone calls and emails

Comprehensive Financial Management

Complete online payment system

Account-specific pricing, terms and limits

Automated invoices and collections

QuickBooks integration

Streamline Your Productivity Workflow

Eliminate manual data-entry from orders to production

Customizable Machine Exports

Automated cut lists and part lists generation

Machine exports in multiple formats (CSV, ORD, DFX, and more)

Custom mapping for catalog and machine optimization softwares

Batch processing for high volume consolidation

Advanced Workflow Automation

Communication triggers at critical workflow stages

Labeling and tracking throughout production

Webhook and API integration with existing systems

Process-specific safeguards to prevent order and production errors

Is Allmoxy right for your component manufacturing?

Produce Configurable Products

Manufacturers with custom sizing, material options, and configuration variations gain tremendous efficiency through Allmoxy's formula-based approach.

Machinery Integrations

If your operation relies on CNC equipment, optimization software, or other digital manufacturing tools, Allmoxy eliminates costly manual data entry.

Process High Volumes

The more order you process, the more dramatic the impact of Allmoxy's automation on your bottom line, allowing you to scale without proportionally increasing staff.

Value Data-Driven Decisions

Component manufacturers who want detailed insights into production efficiency, material yield, and financial performance benefit from Allmoxy's comprehensive reporting.

Empower Manufacturing & Reporting

Gain critical insights and control across your operation

Robust Reporting System

Comprehensive financial and production-based reports

Tag system to filter information by any parameter

Performance and productivity monitoring

Trend analysis for business forecasting

Shop Process Management

Time tracking across production processes

Supply and material management

Inventory allocation and monitoring

Intelligently route jobs to the shop floor for lean efficiencies

Real shops, real challenges, real results

From chaos to confidence

CHALLENGE

Managing increasing order volume while maintaining quality and lead times.

SOLUTION

Implemented Allmoxy’s online ordering with formula-based pricing and direct machine integration.

RESULTS

-

Processing hundreds of customer orders with just two office employees.

-

99% of customers placing orders independently.

-

90% reduction in order error.

-

Expanded market reach beyond traditional geographic limits.

Why Allmoxy is the top choice for component manufacturers

High-Volume Order Processing

Handles limitless number of orders efficiently without bogging down your system or requiring additional staff.

Formula-Based Configuration

Automates complex pricing calculations based on materials, dimensions, and options that are unique to component manufacturing.

Direct Machine Integration

Connects orders to your machining software and production equipment, eliminating manual data entry and reducing errors.

Specialized Reporting

Provides visibility into the metrics that matter for component manufacturing, from order volume to production efficiency,